Japansägen

Das praktische Handbuch für Holzarbeiter

In diesem Handbuch finden Sie alle Informationen die Sie brauchen, um sich direkt mit einer Japansäge an die Arbeit zu machen. Geeignet für mehr und weniger erfahrene Holzarbeiter!

In diesem Handbuch:

– Was sind Japansägen?

– Was sind die Vorteile?

– Wie benutzt man eine Japansäge?

– Wie wählt man eine Japansäge?

Und noch sehr viel mehr!

Index

Kapitel 1

Was man über Japansägen wissen muss

- Was sind Japansägen?

- Was sind die Vorteile von Japansägen?

- Welche Typen Japansägen gibt es?

Kapitel 2

Wie benutzt man eine Japansäge?

- Wie sägt man mit einer japanischen Zugsäge?

- Wie pflegt man eine Japansäge?

- Die Verzahnung Ihrer Japansäge

- Die Länge und Dicke Ihrer Japansäge

- Andere Materialien als Holz sägen

- Erste Hilfe für Anfänger

Kapitel 1

Was man über Japansägen wissen muss

In diesem Kapitel beantworten wir die Frage ‘Was ist eine Japansäge?’

Wir erklären Ihnen gerne, wie sich Japansägen von normalen Handsägen unterscheiden und was die Vorteile sind.

Lasst uns beginnen!

Was sind Japansägen?

Wenn Sie sich für Holzbearbeitung interessieren, dann haben Sie bestimmt schon einmal von Japansägen gehört.

Japansägen sind nämlich Handsägen die von Innenarchitekten, Möbelherstellern, Zimmermännern, Modellbauern und sehr vielen anderen Holzarbeitern genutzt werden.

Die Japansäge wird nicht anders als die westliche Handsäge verwendet, die die meisten von uns gut kennen. Beide werden benutzt um Holz (und manchmal auch anderes Material) zu sägen.

Große Unterschiede zwischen den Japansägen und den westlichen Handsägen merkt man vor allem in der Benutzererfahrung und dem Sägeergebnis. Diese sind nämlich ganz anders als die von einer ‘normalen’ westlichen Handsäge. Lesen Sie schnell weiter!

Was sind die Vorteile von Japansägen?

Haben Sie noch nie eine Japansäge benutzt? Dann ist es wichtig zu wissen, dass sie anders funktioniert als eine westliche Säge. Eine der auffälligsten Eigenschaften der Japansägen ist nämlich, dass es sich um Zugsägen handelt.

Das bedeutet, dass man die Japansäge mit Zugbewegungen führt und nicht, wie eine westliche Säge, durch das Holz drückt.

Die Zugbewegung der Japansägen hat mehrere Vorteile gegenüber einer Druckbewegung.

Die Vorteile einer Zugbewegung

Vorteil 1

Das Sägeblatt einer japanischen Zugsäge braucht keiner Spannung Stand zu halten, wodurch es viel dünner gemacht werden kann. Das Ergebnis ist ein genauerer Sägeschnitt, als bei westlichen Sägen.

Vorteil 2

Die Zugbewegung vermeidet, dass die Säge im Holz stecken bleibt oder sich verbiegt. Dies verlängert die Lebensdauer der Säge.

Vorteil 3

Eine Zugbewegung kostet weniger Kraft und gibt dem Benutzer darum mehr Kontrolle über den Sägeschnitt.

Japansägen sind darüber hinaus mit einer besonderen Verzahnung versehen. Die Zähne werden an drei Seiten messerscharf geschliffen (die sogenannte “Trapezverzahnung’) und äußerst sorgfältig positioniert.

Diese typische japanische Verzahnung schneidet so sauber durch das Holz, dass Schleifen häufig nicht mehr nötig ist.

Der Unterschied zu einer normalen westlichen Säge ist gut sichtbar auf dem Foto hierunter.

Des Weiteren ist es bei den meisten Japansägen sehr einfach ein Sägeblatt zu wechseln. So findet die Säge schnell eine andere Verwendung.

Es ist darum auch meistens nicht nötig die Zähne zu schleifen. Ein Ersatz-Sägeblatt ist einfacher und günstig. Praktisch, wenn man z.b. doch einen Nagel übersehen hat ?

Welche Typen Japansägen gibt es?

Genau wie bei westlichen Sägen gibt es verschiedene Sorten Japansägen. Die am häufigsten vorkommenden Sorten sind die Kataba-, Ryoba- und Dozuki-Sägen. Wir erklären Ihnen gerne die wichtigsten Unterschiede.

Kataba

Die Kataba ist der starke Alleskönner unter den Japansägen. Diese Sägen werden in Japan für Zimmerhandwerk benutzt und sind die zugänglichsten Japansägen.

Die Kataba-Modelle haben in der Regel ein Sägeblatt, welches für Trenn- und Gehrungsarbeiten geeignet ist. Anders als bei Ryoba-Sägen ist das Sägeblatt nur an einer Seite verzahnt.

In manchen Fällen ist das Sägeblatt mit einer speziellen hybriden Verzahnung (M-Verzahnung) versehen. Das macht es möglich mit demselben Sägeblatt auch effektiv Längsschnitte zu sägen.

Ryoba

Diesen Typ Japansäge erkennt man an dem Sägeblatt, das an beiden Seiten geschliffen ist. Normalerweise ist eine Seite für Trennarbeiten und die andere speziell für Längsschnitte gedacht.

Ryoba-Sägen werden als feine Zimmermannssäge und als Werkstatt-Säge verwendet. Zum Beispiel bei Möbelherstellern und Innenarchitekten.

In Japan ist die Ryoba wegen ihrer verschiedenen Verwendungsmöglichkeiten die am häufigsten benutzte Handsäge unter Holzarbeiter.

Dozuki

Die Dozuki-Sägen haben besonders dünne Sägeblätter mit einer sehr feinen Verzahnung. Diese Handsägen werden in der Regel bei feinsten Sägearbeiten eingesetzt (sowohl Trenn-, als auch Gehrungsarbeiten).

Mit Dozuki-Sägen können sehr präzise Sägeschnitte gemacht werden für genau passende Verbindungen, wie beispielsweise bei Bilderrahmen und Schwalbenschwanzverbindungen.

Dozuki-Sägen sind auch erhältlich mit Rückenverstärkung, um das manchmal nur 0,30 mm dünne Sägeblatt zusätzlich zu stabilisieren.

Tipp!

Das sind praktisch dieselben Sägen, die jedoch mit einem ergonomischen Handgriff versehen sind.

Das Sägeblatt kann darüber hinaus einfach mit einem handlichen Druckknopf gewechselt werden.

Kapitel 2

Wie benutzt man eine Japansäge?

Mit einer Japansäge sägt man ein wenig anders als mit einer westlichen Säge.

In diesem Kapitel erklären wir wie es funktioniert und teilen unsere Tipps. So sägen Sie in kürzester Zeit wie ein japanischer Meister!

Wie sägt man mit einer japanischen Zugsäge?

Wenn man zum ersten Mal eine Japansäge benutzt, fällt direkt auf, dass das Sägeblatt dünner und flexibler ist, als bei einer westlichen Handsäge.

Zu Anfang ist es vielleicht ein wenig gewöhnungsbedürftig, aber das Sägen mit einer Japansäge ist wirklich nicht schwer. Das Einzige was man sich merken muss ist, dass man die Säge nie durch das Holz drücken darf. Japansägen sind extrem stark, aber das ist die einzige Möglichkeit sie zu beschädigen.

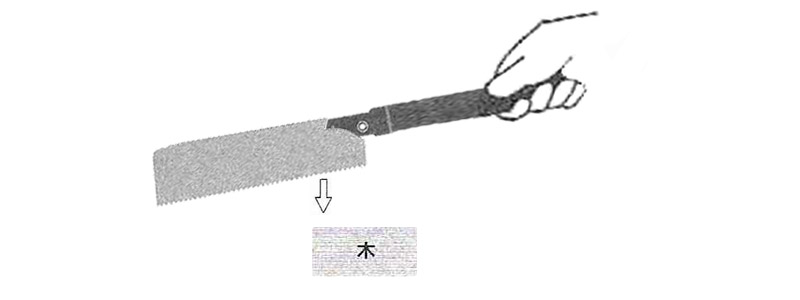

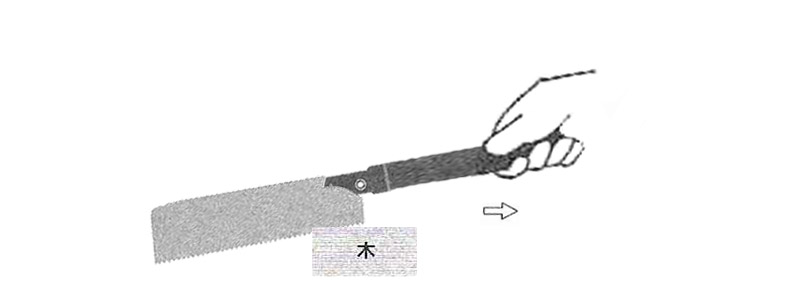

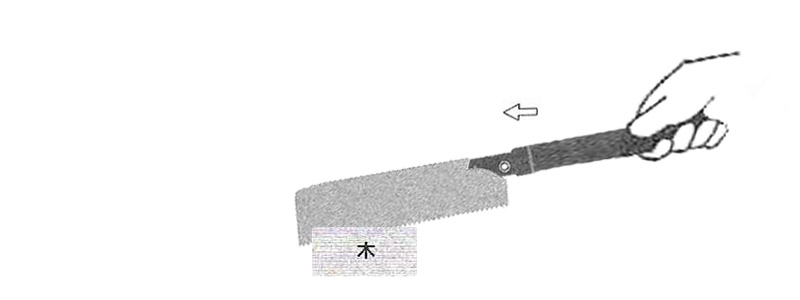

Hierunter erklären wir die korrekte Sägebewegung Schritt für Schritt:

Schritt 1

Der Sägeschnitt einer japanischen Zugsäge fängt hinten, dicht am Griff, an. Halten Sie die Säge an der zu sägenden Stelle und benutzen Sie (vorsichtig!!) Ihren Daumen, um das Blatt ein kleines Stück zu führen, bis im Holz ein Einschnitt ist.

Schritt 2

Ziehen Sie die Säge ruhig zu sich. Lassen Sie die Säge ihre Arbeit machen und setzen Sie vor allem nicht zu viel Druck auf das Holz. Dies kann schwierig sein, wenn Sie eine westliche Handsäge gewohnt sind, da man dabei sogar Druck ausüben muss. Widerstehen Sie der Versuchung!

Beenden Sie die Sägebewegung geschmeidig und zügig, immer noch ohne Druck auszuüben und mit Augenmerk auf der Zugbewegung.

Schritt 3

Bewegen Sie die Säge zurück zur Startposition. Achten Sie darauf die Säge bei der Vorwärtsbewegung nicht in das Holz zu drücken. Das Sägeblatt darf während des Schiebens nicht unter Spannung stehen.

Machen Sie bei den ersten Bewegungen nicht den Fehler zu schnell sägen zu wollen oder stärker zu drücken, sondern machen Sie erst ruhig einen geraden Sägeschnitt. Sie sorgen damit nicht nur für ein perfektes Ergebnis, die Säge wird zudem auch viel länger halten.

Bei den traditionellen japanischen Zugsägen kann man den Griff eventuell auch mit zwei Händen festhalten. Diese Sägen sind mit einem langen Griff versehen, der diese Freiheit bietet. Sorgen Sie dann dafür, dass Sie die Säge nicht zu nah beim Sägeblatt festhalten.

Tipp!

Nehmen Sie sich in Ruhe die Zeit den Winkel zu finden, in dem Sie am angenehmsten sägen. Wir bevorzugen eine nahezu horizontale Bewegung weil wir so am meisten Kontakt mit dem Holz haben, fordert der Sägeschnitt kann die Säge leicht angewinkelt gehalten werden.

Wie pflegt man eine Japansäge?

Die Japansäge dankt ihre besonderen Eigenschaften größtenteils der hohen Qualität des Stahls und der japanischen Verzahnung. Bei sorgfältiger Nutzung wird diese jahrelang gute Arbeit leisten.

Wir teilen gerne ein paar Pflegetipps, die eine lange Lebensdauer und eine sichere Nutzung garantieren.

Unfälle verhindern: Japansägen sind messerscharf geschliffen. Sorgen Sie darum dafür, dass die Säge nie unbeaufsichtigt hinterlassen wird. Nach Gebrauch ist es vernünftig, die Säge an einem sauberen und trockenen Ort zu verstauen.

Die Zähne schützen: Die meisten unserer Sägen werden mit einem Zahnschutz geliefert. Dieser sorgt dafür, dass die Zähne in Topkondition bleiben, auch wenn die Säge im Werkzeugkoffer liegt. Darüber hinaus verhindert die Nutzung des Zahnschutzes unnötige Unfälle.

Das Sägeblatt sauber halten: Halten Sie das Sägeblatt nicht mit Ihren Fingern fest, sondern benutzen Sie immer ein Tuch oder Handschuh. So verhindern Sie, dass das Sägeblatt schmutzig wird.

Sie können die Säge hin und wieder sauber machen. Benutzen Sie dafür ein sauberes Tuch und ein bisschen Öl. Ein Multispray funktioniert gut.

Den Gebrauch der Japansäge üben: Als wenig erfahrener Nutzer ist es vernünftig, sich erst an die Sägebewegung der japanischen Zugsäge zu gewöhnen. So verhindern Sie unnötige Beschädigungen. Mehr Anweisungen finden Sie hier!

Häufig gestellte Frage: Muss man eine Japansäge schleifen?

Das Schleifen der Zähne empfehlen wir (wenn nötig nach intensiver Nutzung) nur bei unseren traditionellen Ryobas und Dozukis. Ihre Sägeblätter sind nicht wechselbar. Die Zähne sind darum nicht extra gehärtet (im Gegensatz zu unseren anderen Sägen). Das macht es möglich sie zu schleifen.

Kapitel 3

Wie wählt man eine Japansäge?

Eine Säge für alle Arbeiten gibt es nicht. Das Geheimnis der japanischen Holzverarbeiter ist, dass sie für jedes Projekt die beste Säge wählen.

Nur so erhalten sie das bestmögliche Ergebnis.

Sind Sie interessiert an einer japanischen Zugsäge, aber wissen nicht welche Sie benötigen? Dann ist dieses Kapitel für Sie!

Die Verzahnung Ihrer Japansäge

Die Verzahnung einer Japansäge ist die ausschlaggebendste Eigenschaft für das Sägeergebnis. Sorgen Sie darum dafür, dass das Sägeblatt, das Sie wählen gut zur Ihrem Verwendungszweck passt. Wir erklären Ihnen was Sie wissen sollten.

Die am besten geeignete Verzahnung für Ihren Verwendungszweck finden Sie, indem Sie sich die Anzahl der Zähne des Sägeblattes ansehen, angegeben als Anzahl Zähne pro Inch oder TPI (manchmal auch PTI). Diese Zahl zeigt wie grob oder fein eine Säge verzahnt ist.

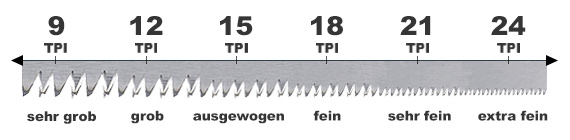

Eine Säge mit einer niedrigen TPI ist gröber verzahnt, als eine Säge mit einer hohen TPI. Siehe auch das Bild unten.

Aber wann wählt man nun welchen Typ Verzahnung? Sie finden unsere Empfehlung hierunter!

Empfehlung (sehr) grobe Verzahnung

Wählen Sie eine grobe Verzahnung von maximal 13 TPI, wenn sie auf der Suche sind nach einer Japansäge die schnell durch das Holz geht. Je gröber die Verzahnung, desto aggressiver die Säge.

Die sehr grobe Verzahnung ist auch geeignet für Gartenholz. Wählen Sie bei Gartenarbeiten aber eine spezielle Astsäge. Diese ist mit einer Beschichtung versehen, die gegen Rost und Harz schützt.

Eine grobe Verzahnung ist nicht geeignet für harte Holzsorten. Die Zähne bleiben möglicherweise hinter den Holzfasern stecken.

Geeignet für: Weiche Holzsorten, grobes Handwerk, nasses Holz, Gartenholz

Nicht geeignet für: Harte Holzsorten, feine Sägeschnitte, Detailarbeiten

Empfehlung ausgewogene Verzahnung

Japansägen mit einer Verzahnung von 14 TPI, 15 TPI oder 16 TPI sind die ausgewogensten Sägen. Die Verzahnung dieser Sägen ist grob genug, um effizient Holz abzunehmen, aber trotzdem fein genug, um einen sehr genauen Sägeschnitt zu erzeugen.

Diese zugänglichen Sägen empfehlen wir für allgemeine Sägearbeiten und präzisere Holzarbeiten.

Geeignet für: Weiche Holzsorten, allgemeine Holzarbeiten

Nicht geeignet für: Harte Holzsorten, sehr feine Sägeschnitte, Gartenholz

Empfehlung feine Verzahnung

Merken: Je feiner/harder der Verwendungszweck, desto feiner die Verzahnung die man braucht.

Achtung! Eine feine Säge geht weniger schnell durch weiches Holz als eine grobe Säge, aber sorgt für ein viel genaueres Ergebnis.

Geeignet für: Harte Holzsorten, sehr feine Sägeschnitte, das genaustmögliche Finish, Detailarbeiten

Nicht geeignet für: Schnell Holz abnehmen, grobe Holzarbeiten, Gartenholz

Mit diesen Empfehlungen wissen Sie schon mal, welche Art Verzahnung (grob/ausgewogen/fein) Sie für Ihren Verwendungszweck brauchen. Die exakte TPI wählen Sie selbst.

Wenn Ihnen ein genauerer Sägeschnitt wichtig ist, dann wählen Sie eine feinere Verzahnung. Wenn Sie lieber schnell sägen, dann wählen Sie eine etwas gröbere Verzahnung.

Tipp!

Planen Sie das Holz im Längsschnitt zu sägen? Dann wählen Sie am besten eine spezielle Verzahnung. Die meisten Ryoba-Sägen sind damit versehen.

Es gibt auch Kataba-Sägen mit hybriden Verzahnungen, die sowohl für Querschnitte, als auch Längsschnitte geeignet sind.

Alle für Längsschnitte geeigneten Sägen finden Sie hier.

Die Länge und Dicke Ihrer Japansäge

Bei manchen Projekten ist es gut auch auf die Dimensionen des Sägeblattes zu achten; die Länge und Dicke. Stellen Sie sich zur Sicherheit die folgenden Fragen:

Wie lang sollte das Sägeblatt sein?

Wenn Sie Balken sägen, muss das Sägeblatt lang genug sein, um den ganzen Balken durchsägen zu können. Außerdem ist ein wenig extra Länge für eine effiziente Sägebewegung angenehm.

Wie dick darf der Sägeschnitt werden?

Manchmal kann es wichtig sein sehr genau mit einer bestimmten Dicke zu sägen. Zum Beispiel beim Sägen der Bünde auf einem Gitarrenhals oder bei präzisen Verbindungen für Bilderrahmen.

Zusammen sind Verzahnung, Länge und Dicke des Sägeblattes die ausschlaggebendsten Faktoren für Ihr Sägeergebnis.

Wenn es an diesem Punkt immer noch mehrere Sägen gibt, die für Sie in Frage kommen, dann hängt die beste Wahl von Ihrer persönlichen Geschmack ab.

Sägen Sie am liebsten mit einer Kataba oder einer Ryoba? Bevorzugen Sie eine traditionelle Säge oder eine Shark Saw? Die Wahl liegt bei Ihnen!

Andere Materialien als Holz sägen

Innenarchitekten, Möbelmacher, Zimmermänner und andere Holzverarbeiter benutzen ihre Sägen normalerweise für trockenes Holz.

Darüber hinaus werden Japansägen auch für andere Materialien verwendet. Zum Beispiel für Eisen, Gips und Kunststoff.

Für diese Materialien gelten andere Regeln als für Holz. Auf Japansaegenshop.com empfehlen wir einige spezielle Sägen für spezifische Verwendungszwecke, die wir hierunter aufgeführt haben.

Kunststoff

Sägen Sie Kunststoffe wie PVC und Plexiglas mühelos mit einer fein verzahnten Japansäge. Die Sägen sind auch gut geeignet für Holz, Parkett, Laminat und Plattenmaterial.

Gips

Benutzen Sie diese kurze Kataba für das Sägen von Gipsplatten, Gipswänden und Wänden aus Gipsblöcken, Plattenmaterial aus Holz, Holzfasern oder MDF.

Erste Hilfe für Anfänger

Für diejenigen die weniger erfahren sind in der Holzverarbeitung, ist es möglicherweise schwierig für ihre ersten Japansägen eine Wahl zu treffen.

Natürlich helfen wir Ihnen gerne dabei, darum haben wir aufgelistet welche vier Sägen unserer Meinung nach für Tischler, die mit Japansägen noch nicht so bekannt sind, nicht fehlen dürfen.

Stark und vielseitig

Diese Shark Saw 112312 gehört zu unseren Favoriten.

Die Schnelligkeit und Effizienz dieser Zimmermannssäge eignet sich gut für allgemeine Arbeiten.

Maximale Flexibilität

Die Shark Saw Pro zweiseitige Säge 112440 ist eine hervorragende und zugängliche Säge für genaue Quer- und Längsschnitte.

Feine Sägearbeiten

Verwenden Sie die Shark Saw Pro Feinsäge mit Rückenverstärkung 112410, wenn eine perfekt passende Verbindung und ein besonders sauberer Sägeschnitt entscheidend sind.

Die Rückenverstärkung sorgt für Extra-Kontrolle während des Sägens.

Holzbearbeitung im kleinen

Die Shark Saw Detailsäge 112214 ist eine handliche kleine Säge. Das flexible Sägeblatt mit 22 TPI arbeitet geschmeidig und äußerst präzise. Dies macht haargenau passende Verbindungen möglich.

Geeignet für Modell- und Instrumentenbau.

Jede dieser Sägen hat ihren eigenen Verwendungszweck, aber Stück für Stück liefern sie einen besonders sauberen Sägeschnitt. Außerdem haben alle ein einfach wechselbares Sägeblatt.

Für die weniger erfahrenen Tischler bedeutet das Flexibilität und Sicherheit, weil das Sägeblatt bei eventuellen Beschädigungen beim anfänglichen Üben günstig zu ersetzen ist.

Kapitel 4

Wie erkennt man Qualität?

Sind Sie auf der Suche nach einer Japansäge? Eine Suche auf Google zeigt, dass es verschiedene Anbieter gibt.

Neben den qualitativ hochwertigen Optionen gibt es auch weniger hochwertige Alternativen.

In diesem Kapitel erklären wir Ihnen, wie Sie eine gute Wahl treffen.

Eine gute Japansäge finden: die Checkliste

Echte Japansägen werden mit besonderem Augenmerk auf Qualität hergestellt. Vor allem die Verarbeitung des Stahls und der Zähne, ist essentiell für die kennzeichnenden Sägeeigenschaften.

Trotzdem gibt es auch Japansägen, bei denen weniger auf Qualität und mehr auf den Preis geachtet wird.

Diese Sägen werden für niedrige Preise angeboten. Zum Beispiel bei günstigen Supermärkten. Das klingt ansprechend, aber das Sägeergebnis und die Lebensdauer dieser Sägen lassen leider zu wünschen übrig.

Zum Glück gibt es einige Tricks, mit denen man schlechte Qualität enttarnen kann. Diese teilen wir in dieser praktischen Checkliste!

Checkliste

▢ Check 1: Verarbeitung des Sägeblattes

Das Sägeblatt muss glatt und eben verarbeitet sein. Kontrollieren Sie, ob das Sägeblatt sich nicht rau anfühlt und keine sichtbaren Unebenheiten zeigt.

▢ Check 2: Verhärtungsmethode

In manchen Fällen sind die Zähne von Japansägen extrem gehärtet. Die Methode der Härtung ist ein gutes Indiz für die Sorgfalt während des Produktionsprozesses.

Wenn die Zähne gehärtet sind, dann sollten nur die Spitzen dunkel gefärbt sein. Übermässige Verfärbungen sind kein gutes Zeichen.

Gut

Nicht gut

▢ Check 3: Qualität der Verzahnung

Drehen Sie das Sägeblatt um, sodass Sie in die Zähne schauen. Können Sie gut sehen, dass die Zähne abwechselnd nach außen gebogen sind (=Setzung der Zähne)?

Bei einer hochwertigen Japansäge ist die Setzung schwierig zu sehen und sehr regelmäßig. Darüber hinaus darf an der Oberseite der Verzahnung keine Verformung sichtbar sein.

▢ Check 4: Handgriff

Sehen Sie sich zum Schluss den Griff gut an. Sitzt das Sägeblatt korrekt im Griff? Ist der Griff gut verarbeitet? Sehen Sie viele überschüssige Klebereste? Diese Merkmale können auf eine schlechte Qualität deuten.

Vergessen Sie nicht, dass auch der Ort an dem Sie die Säge kaufen eine Anzeichen für die Qualität ist. Bei einem Discounter findet man wahrscheinlich keine hochwertigen Werkzeuge.

Kaufen Sie Ihre Säge bei einem Spezialisten, wie Japansaegenshop.com, dann können Sie davon ausgehen, dass Sie die beste Qualität kaufen.